The quality of the produced electronics, and above all the efficiency of the technological process, depends mainly on the technical capabilities of the machines used in production. That is why the devices operating in the production line are subject to increasingly higher requirements. Continuous miniaturization of components and complexity of manufactured applications makes the choice of machines to be more than just a simple comparison of technical capabilities of different manufacturers.

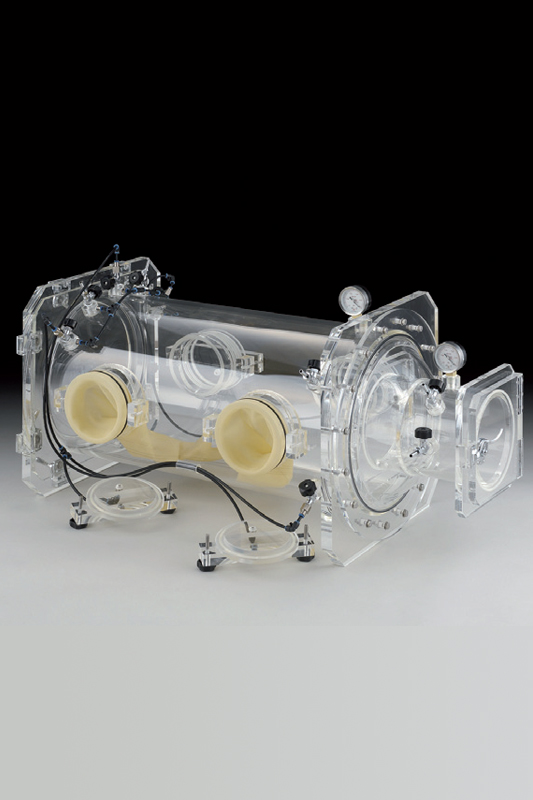

Gloveboxes with a controlled protective atmosphere are the place where production and laboratory processes are carried out. The purpose of the chamber is to isolate the object from the surrounding atmospheric factors. Materials, substances and devices needed for production and laboratory processes are introduced into the chamber through a vacuum feed lock. The purpose of the lock is to adapt the atmosphere surrounding the object being fed to the controlled atmosphere inside the glove compartment. The device is usually equipped with a so-called liquid fuse (Dreschl’s scrubber), which regulates and maintains the overpressure inside the glove compartment.

It also prevents the accidental entry of atmospheric air into the chamber. The interior of the chamber is usually filled with an inert gas (e.g. argon, nitrogen or helium) mixed with hydrogen, so it is possible to provide protection against oxygen atoms to keep the materials in the chamber from oxidazing In many applications, instead of inert gas, air is used which is purified in the chamber with HEPA filters, ensuring the difference in pressure of the air inside the chamber to the room.

By recirculating the atmosphere in the chamber from steam filters (usually through molecular screens) to oxygen filters, a stable environment is created whose parameters we can control. Materials are introduced to the environment prepared in such a way, through the airlock, and are worked on inside the chamber, and once the process is completed, they are removed through the airlock.

In recent years, with the growth of users’ needs, chambers are more commonly installed in clean zones, in so so called cleanrooms or cleanboxes, where the control of air cleanliness is ensured (number and size of particles per m3) as well as humidity level and constant temperature.

Working with a cleanroom makes it possible to process materials before or after the stage of work in the glovebox.

BASIC CONSTRUCTION ELEMENTS AND APPLICATIONS OF CHAMBERS

The gloveboxes are used in many research and production processes, typical applications are working with materials sensitive to moisture and oxygen such as lithium, sodium, potassium, calcium, silicon, various organic and inorganic compounds, films, production and research on solar cells, photovoltaic cells, OLED displays, alternative energy carriers, medical equipment, wireless communication, military applications, electronic devices, metal halide lamps, energy-saving light sources up to work with nuclear applications (e.g. tritium removal). This also includes work in areas such as alternative energy carriers, medical equipment, wireless communication, military applications, electronic devices, metal halide lamps, energy-saving light sources, and even work with nuclear applications (e.g. tritium removal).

It can therefore be concluded that they serve to eliminate external conditions that may affect the material in the glovebox and can therefore be divided into two types: – gloveboxes designed to work with materials sensitive to moisture and air; – gloveboxes designed to work with substances that may cause biological, chemical or radioactive contamination. Devices are most often constructed to a specific order taking into account dimensions and individual needs.

Therefore, the chamber can consist of different modules, but always contains several necessary elements. The most important part is the main element ensuring the tightness of the structure. It can be made of different materials, most often steel with tempered glass windows, but it is also possible to use fully transparent materials.

Gloves are introduced into the chamber through the ports, providing protection against hazardous substances and, of course, ensuring the tightness of the glovebox. Research indicates that the main factor destabilising the atmosphere in the glovebox are cracks in the gloves caused by their mechanical degradation, e.g. caused by chemical substances. The primary means of minimising these types of damage is to select good quality gloves (they must be tested and approved by a Notified Body) and to set up and follow an inspection programme.

Especially in nuclear applications, the selection and inspection of gloves are extremely important tasks. Another part is the sluices for transporting materials into and out of the glovebox without polluting the atmosphere. Very often two air locks are used on both sides of the chamber. Then there are humidity and oxygen concentration sensors (other sensors are also installed many times depending on the process and user’s requirements), a vacuum pump and inert gas cylinders.

NEWS

These basic elements have been known in gloveboxes for more than 60 years, however, the last few years have changed a lot in the design of equipment. Nowadays, more and more often, the gloveboxes are equipped with touch screens connected to a PLC to facilitate atmosphere control and introduce automation of standard activities including service.

The company also uses archiving of environmental records, improved gas purification, fast change-over configurations, extensive chamber designs (including multi-storey installations), advanced oxygen and moisture analyzers, innovative designs of combined locks. The chambers are equipped with systems adapted to the process needs. One of the most popular is the welding system (also laser welding). Welding in oxygen and humidity free atmosphere is a safe solution used in the production of medical products (e.g. implants), microelectronics, jet turbines, or in the creation of titanium castings. Welding in chambers provides the operator with relatively high manual capabilities compared to the use of e.g. welding covers.

It is also a very economical solution. Other common systems installed inside the gloveboxes are: spot welding electrodes, jet plasma burners, e.g. for the production of high intensity discharge lamps (HID), laboratory scales, air dryers, compression presses and instruments, grinding and screening equipment. The gloveboxes can work as stand-alone stations or as production units connected in lines, such as in the production of lithium-ion or lithium-polymer batteries. Working with lithium in uncontrolled weather conditions is extremely dangerous and inefficient.

Therefore, working on batteries requires special conditions for testing, production, storage and disposal. The basic device in this production are gloveboxes, often connected in production lines, which enable simultaneous, uninterrupted work in the whole process for as manyas a dozen several operators. In Poland, work on such tasks is carried out in several centres, e.g. at the Wrocław University of Technology, in the Department of Polymer and Carbon Materials in a team led by Professor Jacek Machnikowski. The pharmaceutical and medical industry also uses glovebox lines in work requiring sterility, isolation from microbiological agents, testing of highly active compounds, chemotherapy or powder processing.

GLOVEBOX MANUFACTURERS

A bit stereotypically, many people assume that important chamber manufacturers can be found mainly among German and French companies. Meanwhile, also among Polish companies we can find suppliers with many years of rich experience and an interesting portfolio of realizations. An example is Renex from Włocławek. Since the choice of a glovebox requires close cooperation with its manufacturer, we should seriously consider the choice of a Polish entity that knows the specificity of the domestic user, Polish standards and legal requirements, and can quickly carry out a needs analysis at the customer’s premises and carry out the overall project together with the selection of other elements (such as creating a clean zone) and providing effective service and professional advice. Not without significance is also the fact that Polish prices are about 30% lower than European competitors, which constitutes yet another reason for choosing a domestic, proven supplier.