Ergonomic tools improve safety and comfort and significantly increase productivity. An outline of the issues related to their design and implementation is presented below on the example of hand tools.

Hand-held tools are instruments built on the basis of simple, commonly understood ideas and therefore, apparently, should not pose particularly ambitious challenges to designers and technologists. However, an in-depth analysis of the conditions of use of the tool, expectations of its performance, safety, comfort, durability, etc., must be taken into account during design.

This results in a significant increase in the complexity of the implementation process and the need to introduce appropriate research procedures to ensure the acquisition, processing and interpretation of the most comprehensive and reliable data possible. Changes in the technology of electronic components and systems, such as the design of housings and leads and the method of assembly, require the development of appropriate tools and equipment used in the manufacture and servicing of electronic devices.

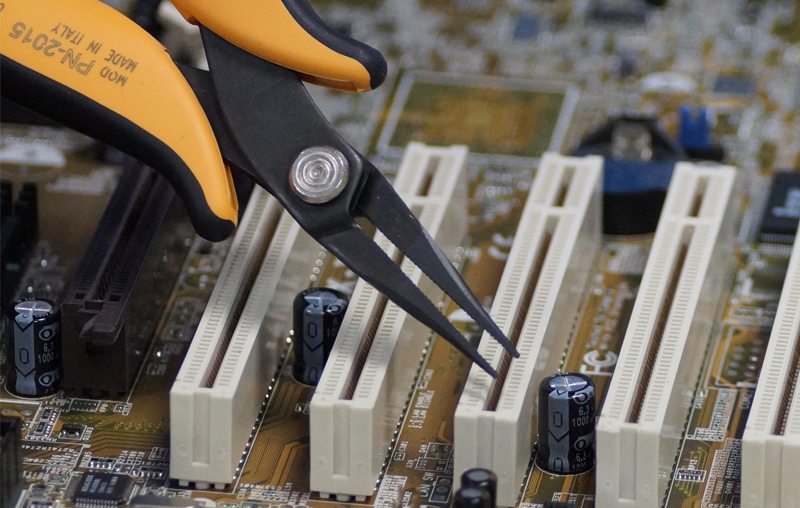

With the already common miniaturization, there is still a growing demand for specialized high-precision equipment designed for specific tasks, such as disassembling the system in the PQFP-304 enclosure. On the other hand – the unique SMD components and circuits are accompanied in some devices by muscular” high-power elements, cables with large cross-sections, solid sockets, etc.”. There is no possibility to use universal tools in such cases. They will not provide the required functionality and efficiency of work, and may cause damage; they may also be damaged themselves. In professional use, it is essential that the tools are used frequently and for a long time. This has inevitable consequences in terms of effectiveness, especially in terms of efficiency, and also in terms of workers’ health.

Combining certain functional features with ergonomic requirements is difficult and few manufacturers, such as Piergiacomi, Gebra, Lindström, PACE, are successful in focusing attention (and adequate resources) on specially developed and systematic research.

The starting point for such research is the identification of areas for improvement of the tools and the adoption of core objectives in each of them. The methodology is then adopted. How this looks in practice can be traced back to Lindström, a manufacturer of professional hand tools for various industries, including electronics. In the research and development programme called Ergo, a number of requirements for safety and ergonomics for modern tools were formulated, grouping them into three categories: A good tool should minimize the risk of direct injuries, such as cuts, abrasions, bruises, etc. Therefore, it must not have sharp edges on the handle, it should prevent accidental contact with working parts, exhibit anti-slip properties, allowing a firm grip under load, etc. (Figure 1).

A good tool should minimise the negative health effects that may result from prolonged use. This condition makes it necessary to achieve, among other things, the following characteristics: weight suitable for the intended use, handles which protect against low high temperatures, minimisation of the muscular tension involved in carrying out the activity over a long period of time, as large a surface area of the handle as possible, allowing the load on the hand and hand to be distributed evenly, high efficiency with as little operator effort as possible, good balance, vibration damping (Figure 2).

A good tool should make work easier. The possibility of using it in different positions, simplification of adjustment, easy and reliable grip, resistance to greases or fats are some of the basic requirements formulated in this respect. In addition, it is desirable that the tool is available in different dimensions, according to the variety of possible applications.

Aiming to achieve the best results in these areas, the leading manufacturers assume that a good professional tool can only be created if the design process includes meticulous tests, carried out under real conditions, i.e. at specific users, whose characteristics characterize well a certain group of potential clients – recipients of the prepared offer.