With the growing market demand for high-end, flexible and integrated technology solutions for assembling electronics, YAMAHA will present three new, reliable machines at Productronica 2013: the AOI 3D inspection device, the AOI Dual LANE system and the high-speed YSD dispenser.

RENEX as an authorized distributor of YAMAHA robots

Renex, being an authorized distributor of Yamaha, enables to carry out customer application tests, production preparation and training on equipment in a demonstration line located in the Technology Centre in Włocławek. Customers from Europe are constantly looking for devices to improve the efficiency of electronics production.

To meet their expectations it is necessary to constantly increase the level of automation and integration of equipment on production lines. Therefore, following the success of the YS series pick and place machines, combined with a comprehensive solution that integrates the YSP printer with the AOI YSi-12, Yamaha will showcase new equipment at this year’s Productronika, enabling even deeper integration of production equipment.

These will be a YSD dispenser and 3D AOI. There will also be an AOI Dual LANE inspection system, which, together with a solder paste printer and an automatic assembly machine for YSM40 components, enables operation in the Dual Lane line. In turn, the YC8 machine will be presented as a device for final assembly of irregularly shaped components. It is worth to get acquainted with the possibilities that are hidden in these products.

YSD dispenser

Yamaha has been designing and manufacturing solder paste dispensers since 1987. Many years of experience have resulted in a high market position, with leading solutions for such systems, which stand out even in the demanding Japanese market. In recent years the requirements in the market for SMT machines have become much higher and geared to increasing productivity.

The answer to this trend is YSD – a fast, high quality, multifunctional dispenser that provides significant improvements in dosing time and efficiency, while providing many new, useful features such as non-contact dosing, in-line dosing and much more.

YSD is built on the same hardware platform and is based on the same software as the other Yamaha devices, which is important in terms of ease of service and continuity of production. By using the YSD dispenser together with the YS series surface-mounting machines, we not only achieve a high level of assembly efficiency, but also make efficient use of the available hall space.

The YSD dispenser is ideal for the implementation of new products and for prototype production. The ability of the device to dispense with investment in stencils and the ability to make immediate changes to the design provides significant savings in production.

Quality

Yamaha’s devices are fully compliant with the latest quality and technology requirements of the electronics industry. These devices are designed and manufactured at Yamaha’s parent plant in Japan, always using the latest technology, proven materials and skilled personnel.

The design of these devices allows them to be prepared to operate at full capacity 24 hours a day, 7 days a week.

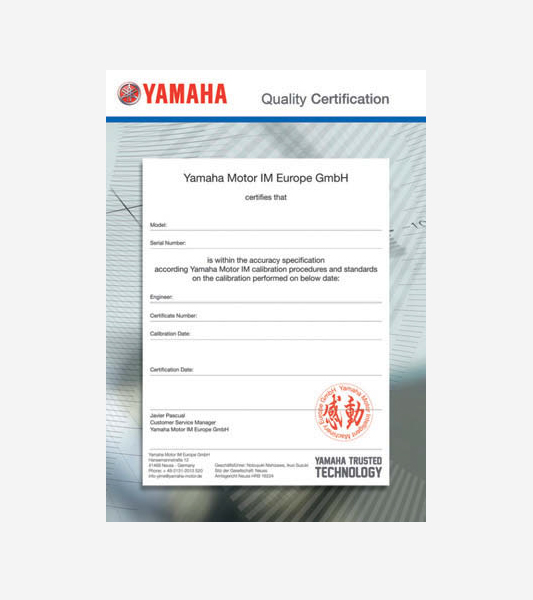

This quality enables users to reduce their operating costs, making them more competitive on the market. In addition, Yamaha is the first supplier of SMT equipment that is committed to actually meeting its declared quality standards and provides a written warranty to that effect – the manufacturer’s responsibility is confirmed by the product quality certificate.

Certificates of quality

The “Yamaha Quality Certificate” is a unique service in the global SMT industry. The biggest benefit is the exclusion of unexpected costs associated with the renovation of equipment. Yamaha ensures that the maximum annual cost of spare parts necessary to maintain the equipment in operation will not be more than 1.5% of the original investment. The “Yamaha Quality Certificate” is valid for all new products in the company’s portfolio, including stencil printers, automatic assembly machines and inspection equipment.

With proper servicing, Yamaha guarantees the validity of the ” Certificate of Quality ” for 8 years from the moment of installation. At regular intervals, certified Yamaha engineers perform full maintenance of the equipment, including calibration. Only original parts and components are used during service, and equipment users are trained by Yamaha certified engineers.

Distribution and demonstration of the operation

The manufacturer’s own assembly line for the assembly of components requires the use of multiple components that bring individual devices together in a line, such as loaders and unloaders, spool changers, conveyors, carts or racks.

All of these elements of Yamaha’s production line and maintenance services are available in Poland through an authorised distributor, Renex. Knowledge of the machine specifications should never be a decisive factor in choosing a particular machine.

That’s why Renex allows comparison of machine operation under real production conditions – at the new Technology Centre in Włocławek, where individual elements of the production line are presented. As part of the configuration and installation, Renex conducts the entire production preparation process, including:

- development of the production process, including support in the selection of BOM elements, in order to select the process in an optimal way,

- testing applications on the production line at the Renex Technology Centre in Włocławek,

- training of production workers on preferential or reimbursed terms, in accordance with international IPC certifications and tailored specifically to the needs of the company.

We encourage you to ask questions and contact the engineers designing hardware solutions. See you at Productronica, in hall A3 at stand 323.