Properly selected floor covering undoubtedly enriches production halls aesthetically, giving them an innovative and aesthetic look. However, in some cases, the choice is not only determined by the appearance, colours or catalogue card data. In the electronics industry such flooring must meet strict technical requirements.

Restricting the generation and flow of electrostatic charges is a major objective in areas protected from ESD. In EPA zones, where component assembly and other manufacturing processes take place, in mechatronics and the IT sector, the selection of the right antistatic liner plays a key role. Not only does it dissipate electrostatic charges, but it also minimizes their formation, already at the contact between the shoe sole and the floor. Another industrial environment that faces the problem of choosing the right flooring material is the high-traffic areas where the surface is exposed to abrasion and other damage. They cause the antistatic properties to deteriorate quickly in this situation.

PROPER FLOORING

Forbo Flooring has been the best known brand among the discussed antistatic protection solutions for over 35 years. The available Colorex antistatic flooring is designed for industrial applications and complies with all industry standards and norms. Already at the stage of choosing the right product from the Colorex family, the manufacturer offers a lifetime guarantee of conductivity, unique dimensional stability, low plasticizer content and thus extremely low emissions of volatile substances. The product is characterized by a smooth surface, high resistance to loads and, most importantly, full repairability. The latter property is a distinguishing feature of the antistatic Colorex floor.

UTTERLY REPAIRABLE

Colorex provides a 100% repairable surface. Deep scratches or other serious damage can be repaired by heat welding. In turn, surface damage such as burns, abrasions or decolorisation can be removed by grinding and polishing. The entire repair can be done with easly available tools and on your own.

All this serves to maintain safety and regain the original aesthetics of the floor – which other carpets cannot provide.

MORE THAN RESISTANCE

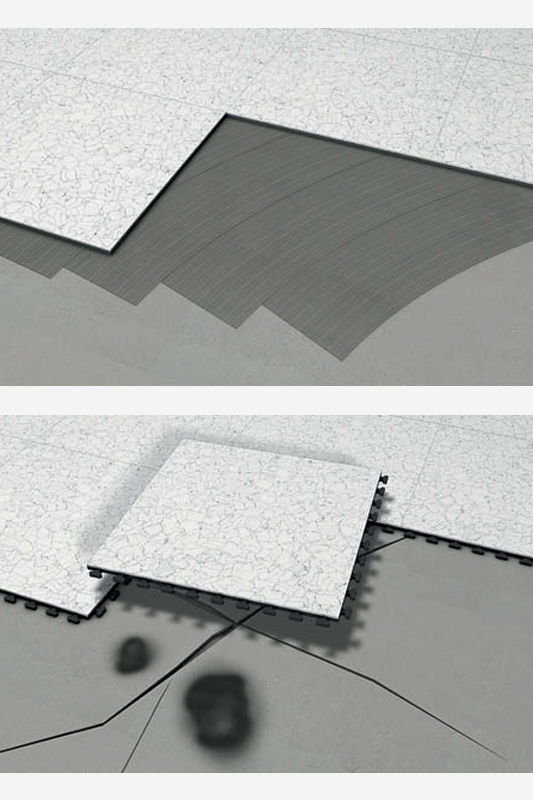

Repairing an industrial floor can be very time consuming and expensive. Downtime caused by the need to move machines or dismantle them and the cost of preparing the subfloor can contribute to an increase in maintenance costs. Colorex EC/SD PLUS flooring is a high quality system, the concept of which is based on laying tiles of antistatic material on a mechanical subfloor in an adhesive-free system, especially in places where expensive subfloor preparation and long downtimes are unacceptable. The installation of the tiles is carried out without any disruption of work and the floor can be used immediately. What is more, there is no special need to prepare the subfloor. Thanks to the honeycomb-shaped bottom layer, Colorex Plus facilitates airflow.

The joining of the antistatic elements is done by means of a unique hooking system that remains invisible. Colorex Plus is available in the EC version – conductive and SD – dissipating static charges. Additionally, the offer includes an antistatic version for places that do not require conductivity. The whole range is complemented by a model whose surface is extruded, which additionally makes it anti-slip. It is worth adding that they can be combined with other Colorex Plus tiles. The complete solution is created, apart from the tiles, by a collection of ramps, slats and plinths which is a finishing touch to every floor.

Colorex Plus can also be installed as a working island, as it does not necessarily have to be installed from wall to wall. Special ramps, which are part of the system, make it easy to drive to such an island and are available in grey and the colours of standard collections, as well as signal colours on request.

THE GROUND DOES NOT MATTER

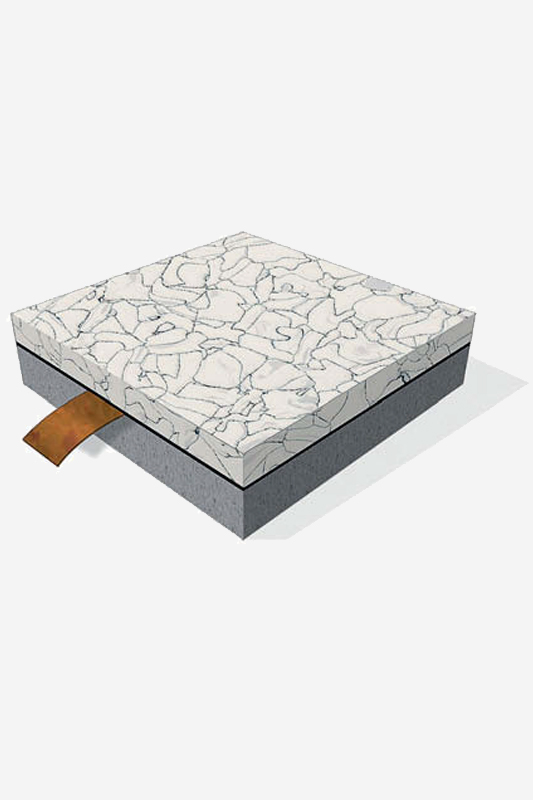

Colorex tiles can be glued to concrete substrates. Such installation is usually carried out using conductive ground, copper tape and conductive adhesive. When underneath the Colorex carpet, a copper tape is glued and discharges charges to a ground point. When there is no requirement for conductive current, it is sufficient to use ordinary base layer and adhesive. Colorex glued to the concrete substrate can withstand high mechanical loads (such as forklift truck wheels) without damaging the carpet. It is possible to weld the tiles with string, which is e.g. required in cleanrooms. It is worth remembering that one of the features of Colorex tiles is that they do not shrink, so properly made weld does not peel off.

SPECIAL APPLICATIONS

Colorex is often installed on raised floors in cleanrooms and data centres and server rooms.

Thanks to the unique properties and strength of the tiles, manufacturers of raised floors can prepare every possible construction depending on the place of application. As the tiles have extremely low emissivity and dense structure, they can be perforated for ventilation systems. This is an important advantage when installing raised floors.

SUMMARY

Wide range of use of Colorex flooring, resistance to heavy traffic and easy repair without sacrificing aesthetics make it prime choice over other alternatives. However, it should be remembered that the choice of the right solution is not determined by knowledge of the technical data and the catalogue card alone.

An important factor determining the purchase and equipment, is the possibility of checking the described solution in service or production conditions. For this reason, Renex has been offering for several years now, in the demo-room in Włocławek, not only the testing of equipment on applications supplied by the customer, but also the possibility of testing the properly prepared and laid floor on an area of 800 m².