Experts in high-tech sectors (such as electronics, automotive, defense, medical, aerospace, and others) must adhere to performance and safety standards that tolerate no errors. Electrostatic Protected Areas (EPA) are a crucial component of the infrastructure in these industries, protecting sensitive electronic components from potentially catastrophic damage caused by electrostatic discharge (ESD). Creating EPA zones is a process that requires careful consideration of several key elements to ensure compliance with standards, durability of the construction, and minimal disruption to daily operations.

Passing audits and adhering to applicable standards

Passing audits and adhering to current standards are essential elements in the process of creating Electrostatic Protected Areas (EPA) in high-tech sectors. Professionals in these fields are fully aware that their facilities must meet strict standards related to electrostatic discharge risks, which can be not only dangerous but also costly in the event of damage to valuable electronic components.

The first step towards renovating EPA zones is ensuring full compliance with current standards related to electrostatic discharge. In Europe, the IEC/CEI 61340-5-1 standard serves as a key reference, outlining the requirements for electrical and electronic equipment that can be damaged by electrostatic discharges of 100 V or more. Adhering to these standards is not only a legal requirement but also a crucial element in maintaining a safe and functional work environment.

Engaging in the audit process and understanding the standards is particularly important to avoid potential costly equipment damage, production delays, and other negative consequences that may arise from non-compliance. Therefore, the audit and compliance process requires continuous monitoring and evaluation to ensure the facility remains in line with current regulations.

In the absence of in-house specialists, consulting with external experts (coordinators, ESD specialists) or obtaining certification from recognized certifying bodies to confirm compliance with standards is beneficial. This approach not only helps minimize risks associated with electrostatic discharges but also builds trust among customers and business partners, demonstrating that the company prioritizes safety and compliance with standards.

Choosing the right materials

The second crucial stage in the process of renovating EPA zones is the proper selection of materials to be used in their creation/adaptation. These materials should be chosen with the aim of meeting the rigorous standards characteristic of the high-tech industry, especially regarding electrostatic discharge.

ESD floor coverings, both new and those undergoing renovation, are the first line of defense against electrostatic discharges that can be fatal to sensitive electronic components. Such coverings must be resistant to various mechanical loads, such as heavy loads or the movement of machines and carts, which are everyday occurrences in many industrial plants. Chemical resistance is equally important, as many industrial processes involve the use of various chemicals that can react with floor materials.

ESD floors must be resistant to acids, bases, and detergents often used in the high-tech industry. When selecting materials, attention should be paid to their durability, wear resistance, and ease of maintenance. Long-term durability and low maintenance requirements can significantly reduce operating costs associated with maintaining EPA zones in proper condition. Additionally, materials should be chosen to support the functionality and operational efficiency of the zone, without negatively impacting the overall performance of the facility.

Minimizing the impact of work on ongoing operations

In high-tech industries, maintaining production continuity during the adaptation of EPA zones is crucial, as any downtime is costly. A strategy to minimize such downtimes could be phased flooring installation, allowing production processes to continue during adaptation work. Choosing ESD industrial floors that are quick to install and do not generate disruptions such as dust or unpleasant odors can significantly minimize downtime and reduce the impact of renovation work on ongoing operations. Introducing a clear communication plan and work schedule, along with the possibility of conducting renovation work outside production hours, can also contribute to the effective execution of the renovation project with minimal impact on production operations.

Choosing a solution that meets these four requirements

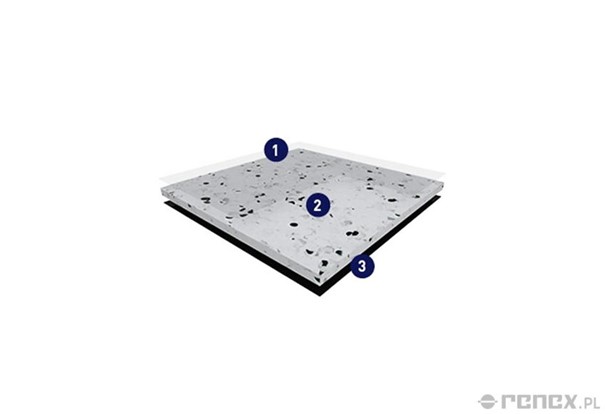

To meet standards related to protection against damage caused by electrostatic discharge, standards regarding tightness and resistance, as well as performance requirements, Gerflor has created the GTI EL5 series, in line with the philosophy of “Raise Your Standards.”

The electroconductive and antistatic floor panels from this series can be installed in all high-tech industrial zones, such as production, packaging, and storage areas for ESD-sensitive products, cleanrooms, and data centers. These panels are ideal for renovating EPA zones because they are quick to install, require no specialized tools, or glue, eliminating the need for drying time. Gerflor Group, a global leader in the production of specialized flooring, offers products for various sectors, such as healthcare, laboratories, food processing, and modern technologies.

Gerflor’s product range includes a wide variety of types, designs, and colors of floors, available in several fastening systems – including glued to the substrate and laid like puzzles. RENEX Group, specializing in providing advanced solutions for the electronics manufacturing sector and related industries, offers Gerflor flooring, including the specialized GTI EL5 Connect flooring. RENEX Group is known for providing a comprehensive offer dedicated to the electronics manufacturing industry. The offer includes a wide range of equipment for EPA and cleanroom zones, including REECO brand antistatic furniture and clothing of their own production. Additionally, the Group provides consulting, training, and service related to all delivered products, electronics production, robotics, and automation.

For those interested in RENEX Group’s wide offer, including Gerflor flooring, we invite you to contact RENEX Technical Sales Advisors. Additionally, we encourage visiting the RENEX TECHNOLOGICAL CENTER, where it is possible to see and test the elements of the comprehensive EPA zone equipment offered by RENEX Group. This gives potential clients the opportunity to directly familiarize themselves with the high-quality products and services offered by RENEX Group, which can contribute to further cooperation and the development of innovative solutions in the industry.