Solderstar, a leader in providing temperature profiling equipment, has announced that it will introduce significant innovations in the industry during the upcoming Productronica 2023 trade fair, which will take place from November 14-17. The company will showcase its latest technological advancements at booth A4.246/4, including the premiere of a revolutionary soldering process control technology that aims to transform measurement in advanced soldering applications.

Reflow Shuttle – a breakthrough in reflow process verification

Solderstar aims to stand out in the market with the Reflow Shuttle, a groundbreaking device designed for precise monitoring and verification of the reflow soldering process. The Reflow Shuttle allows for accurate measurement of key parameters in the reflow process, resulting in unparalleled accuracy and insight into soldering processes. This is in response to the growing demands of modern reflow soldering devices, utilizing advanced sensors to measure temperatures in the upper and lower profiles, enabling detailed analysis of oven performance. The Reflow Shuttle not only evaluates temperature profiles but also monitors heating uniformity and machine vibrations in three axes, which is crucial for the final product’s quality.

This equipment also enables control of the production line speed and, for processes requiring vacuum, offers optional modules to measure vacuum levels.

Reflow Shuttle O2 – precise soldering quality control

Among the novelties, Solderstar will present the Reflow Shuttle O2, a device that measures oxygen levels in the soldering process. Controlling oxygen levels is crucial because it prevents the formation of oxides that weaken solder joints. The Reflow Shuttle O2 allows for precise monitoring of oxygen content and optimization of nitrogen usage, resulting in stronger and more reliable connections. Mark Stansfield, Managing Director of Solderstar, emphasizes that the main goal of the Reflow Shuttle O2 is to provide manufacturers with real-time insight into their reflow soldering processes, allowing for operational optimization and ensuring the highest product quality.

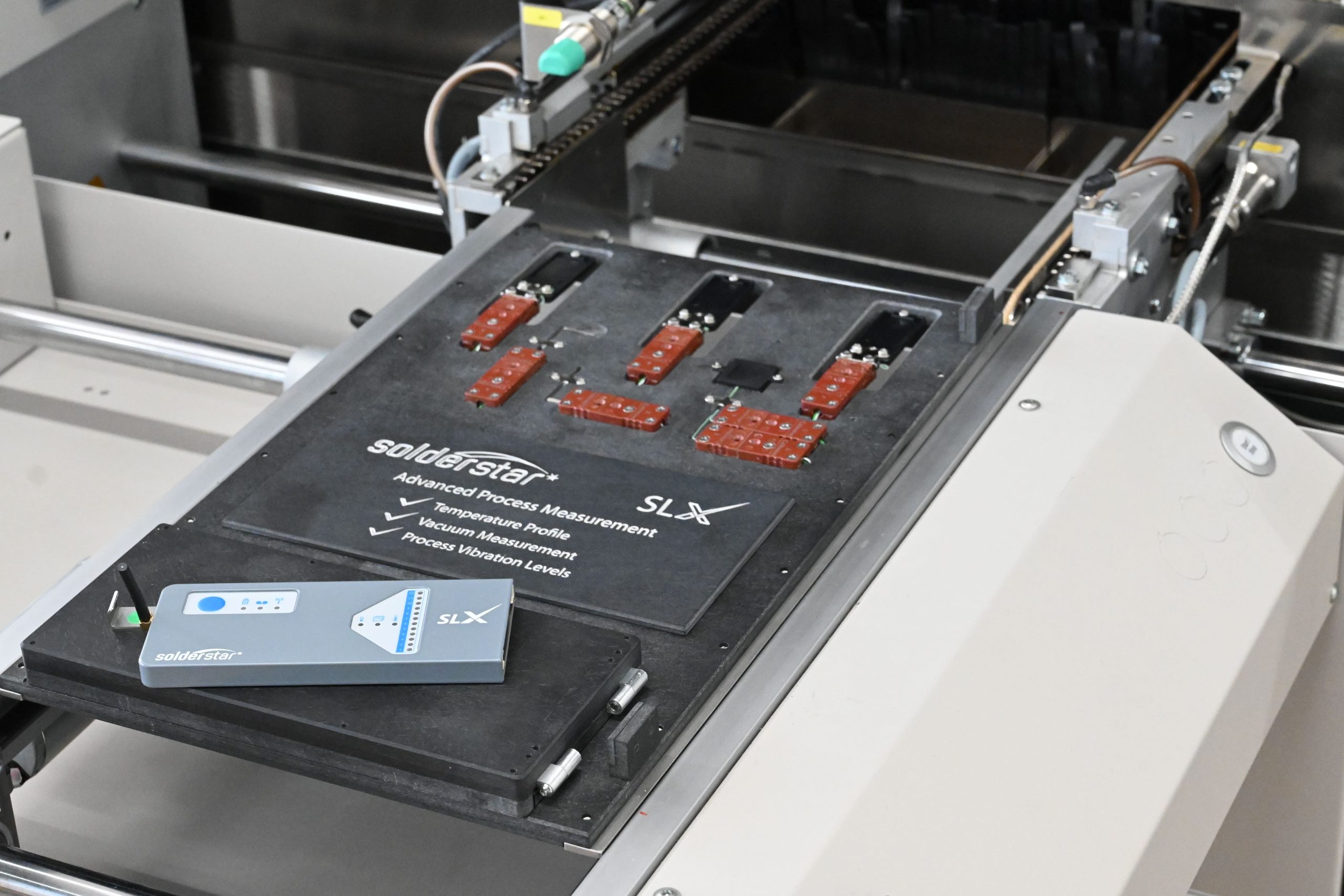

SLX: Ultra-Compact recorder for electronics production

Solderstar’s booth will also feature other innovations, including the centerpiece of their offering – the SLX recorder. This device is crucial for monitoring and recording soldering parameters. The SLX stands out for its precision, durability, and ultra-compact size, making it an ideal tool in a dynamic production environment. Battery-powered, the data logger allows for mobile and flexible use in various conditions. Moreover, the SLX recorder is designed to seamlessly integrate with SMARTLink thermal barriers or other process accessories, automatically configuring itself for data collection.

It is this configuration-free convenience that makes the SLX a valuable tool in Solderstar’s technological arsenal. It enables quick docking and work initiation, which is essential in the fast-paced environment of today’s electronics production. The intuitiveness and automation of the configuration process save time and resources, thereby increasing production efficiency.

Three decades of leading temperature profiling technology

With its experience and innovative solutions, Solderstar has become a leader in designing and manufacturing temperature profiling systems. With offices in the UK, USA, and a technical center in Germany, it offers comprehensive support and solutions for electronics manufacturers. The Solderstar team, leveraging over 30 years of design experience and in-depth industry knowledge, continually strives for excellence in product innovation and customer service.

Solderstar, a pioneer in lead-free production, continues the tradition of introducing innovations that meet the needs of the dynamically developing electronics market. With its designed equipment and software, the company streamlines the entire profiling process for various soldering methods, setting new industry standards.

Solderstar’s products embody advanced functionality, durability, and ease of use, resulting in improved quality and production efficiency through continuous process verification. At Productronica, the company hopes to showcase its technologies and share knowledge about this groundbreaking product with a wide audience.

Visitors to Productronica, taking place from November 14-17 in Munich, Germany, are invited to explore Solderstar’s groundbreaking solutions at booth A4.246/4. Solderstar’s team of experts will be available to provide detailed information, demonstrations, and answers to technical questions.

Solderstar products available at RENEX Group

For years, RENEX Group has been providing advanced temperature profiling technologies to customers in Europe. Their distribution experience allows for the widespread dissemination of Solderstar innovations, such as the Reflow Shuttle and SLX recorder, ensuring reliable technical support and product availability.

Through this proven partnership, customers are assured access to products that define standards in temperature profiling, benefiting from RENEX Group’s expertise and after-sales services. This partnership guarantees that Solderstar products are available and supported by a robust distribution network, which is invaluable for electronics manufacturers aiming to optimize their production processes.