The International Trade Fair for Innovative Industrial Solutions ‘Warsaw Industry Week’ took place in Nadarzyn from 7-9 November.

As part of the event, the RENEX Group had the opportunity to present a comprehensive range of products for the electronics and other specialist industries. The main focus of the exhibition was to present the novelties of REECO’s own brand offerings – a soldering robot with an automatic rotary table, a dispensing robot and automatic transport systems for production lines, as well as YAMAHA robotic solutions.

REECO Robots

As part of the stand, visitors were able to test the potential of REECO Robots – a range of ready-to-use devices that can be implemented in an operating production line without the need to design complex technical solutions and integration processes. The RENEX Group stand showcased the capabilities of two robots: a dosing robot (Conformal Coating) and a soldering robot with a rotary table. These robots are the latest offerings in a series that were first presented to the European public less than a year ago. Demonstrating their capabilities was one of the key elements of the RENEX Group stand.

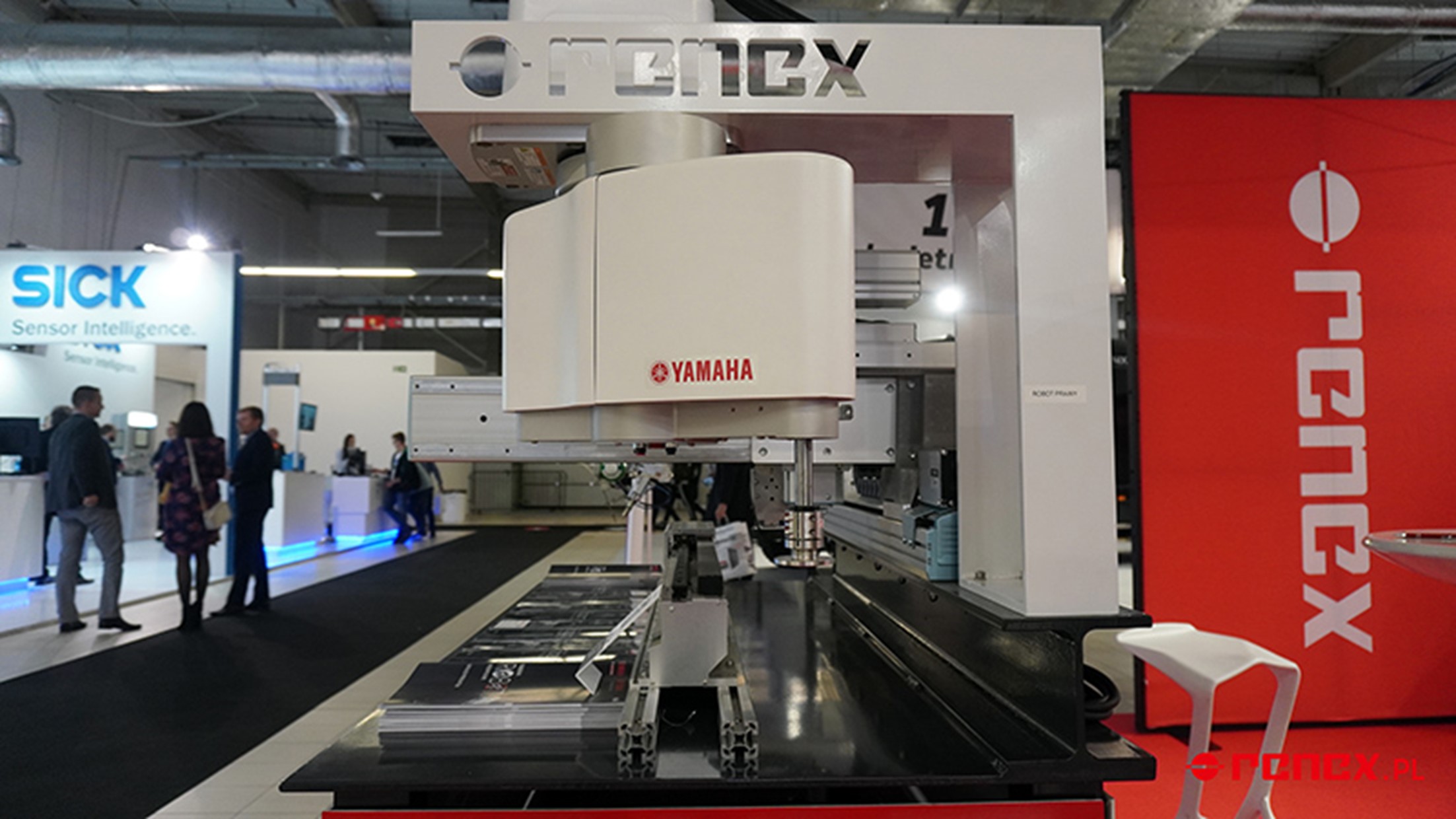

YAMAHA Robotics at WIW

As part of the RENEX Group’s stand, a wide base of YAMAHA robots was on display, including devices from the SCARA series. This type of equipment allows for very fast, repetitive and precise movements, providing a versatile mobile base on which the user himself places the tools of his choice according to his needs. YAMAHA’s products include SCARA industrial robots with arm lengths from 120 to 1,200 mm, and maximum payloads of up to 50 kg. An important part of the show was the visit of YAMAHA representatives – Product Marketing Manager EMEA Ibrahim Buge and Sales Manager – Jumpei Ninomiya. The visit allowed for an exchange of experiences and visions for further cooperation.

Flagship REECO workstation

The RENEX Group’s flagship product, the REECO Premium Electric Antistatic Table with electrically adjustable table top height, was not to be missed at the exhibition. Thanks to this solution, the user can frequently change the working position between sitting and standing, which reduces the risk of occupational diseases. This feature also allows the workstation to be easily adapted to the needs of a particular person or task. Visitors to the fair also had the opportunity to see the REECO range of anti-static furniture. This line of specialized industrial furniture was developed with the electronics manufacturing and repair industry in mind, although it is now becoming increasingly popular with customers from other industries due to its quality.

The modularity and compatibility of REECO’s furniture was also showcased at the trade fair – features that create ergonomic workspaces that reduce the risk of occupational illnesses and increase process efficiency. In addition, thanks to these features and the consistent quality and availability of the range maintained over the years, users are able to expand and change their workspaces seamlessly. The RENEX Group places great emphasis on consultancy, training and research activities to support the development of its partners in many sectors. For this reason, in addition to being able to see equipment and devices, it was also possible to consult with experts from the RENEX TECHNOLOGY AND TRAINING CENTRE at their stand.