RENEX Group has released a video discussing projects and spheres of cooperation with key foreign partners in 2021.

In a video made in the course of the recent Productronica Fair in Munich, RENEX Group discusses the spheres of cooperation with its key foreign partners. Included in the material are such global brands supplying equipment and support to the electronics industry as YAMAHA, HELLER, IPC, SOLDERSTAR, PACE, JBC, TAGARNO and MICROCARE.

“Working with global brands is one of the pillars of our business. Providing comprehensive support to the electronics industry – that is, encompassing a full range of world-class products and services – is key for us. A large part of this mission is accomplished in-house by providing our own products such as REECO furniture, clothing, robots, and equipment, the CLEANROOM operations, and the RENEX TECHNOLOGY AND TRAINING CENTER. The remaining part of our mission is realized through the cooperation and supplying to the Polish and Central-European market the products of the biggest and most recognized world brands. (…) The last Productronica trade fair was for us an opportunity to meet and sum up, together with our global partners, the areas of our cooperation and successes in 2021”. Commented Mrs. Marzena Szczotkowska-Topić and Mr. Predrag Topić – owners of the RENEX Group.

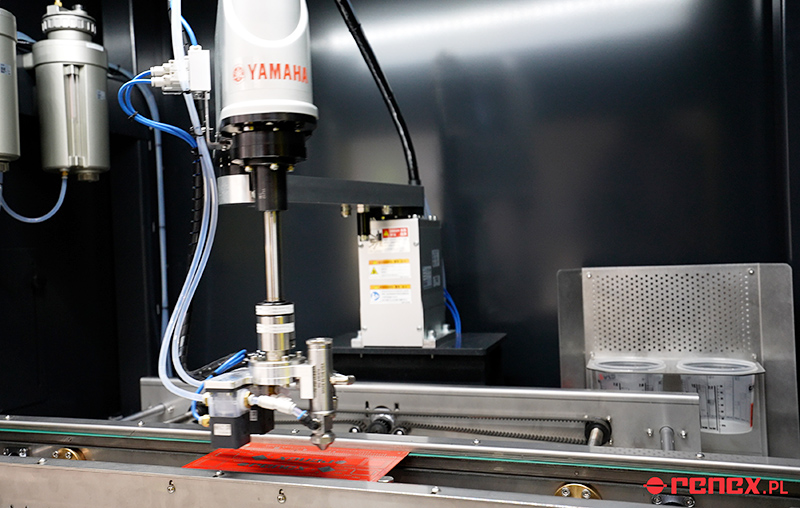

At the Productronica Fair, RENEX Group presented three robot models: REECO Soldering Robot, REECO Dispensing Robot and REECO Coating Robot. This section allowed to illustrate the capabilities of these devices in various applications, using their operation in the production of electronic packages as an example. The key element of the section was the presentation of the capabilities of the Soldering Robot in terms of automation of the process of the PCB through-hole soldering. Moreover, the operation and wide range of applications of the Dispensing Robot based on a volumetric pump was presented. This device allows the application of substances with high viscosity, such as adhesives or silicones. The presentation was complemented by the Coating Robot – one of its functions is to apply conformal coatings, which are more and more widely used to protect electronics against external conditions. The presentation was also extended with elements from REECO’s equipment range – linear conveyors. Devices of this type allow to extend production lines based on REECO Robots and units of other manufacturers.

The Fair visitors had also the opportunity to get acquainted with the REECO Antistatic Furniture offer. This line of specialized industrial furniture was developed for the electronics production and repair industry, although nowadays, due to its quality, it is gaining popularity among the customers from other industries. The products of this line are based on steel construction covered with coatings with antistatic properties, which makes them suitable for use in so called EPA zones, where advanced electronics are produced and repaired. At the Fair, the modularity and compatibility of REECO Furniture was presented – features that allow to create ergonomic workspaces that reduce the risk of occupational illnesses and increase process efficiency. Moreover, thanks to these features and the consistent quality and availability of the offer maintained over the years, users have the possibility of smoothly expanding and modifying their workspace. RENEX Group stand featured, among other products, one of the flagships of the series, the Premium Electric Antistatic Table with electrically adjustable table top height.