RENEX Group – distributor of YAMAHA has informed about the development of cooperation between YAMAHA SMT and the Lithuanian company Elgama.

Elgama from Vilnius develops and manufactures smart electricity meters for residential, industrial and commercial applications. Its products are certified according to leading international standards and exported to more than 25 countries. The company places great emphasis on development. More than 20% of its employees are directly involved in developing the next generation of products. Working with selected partner companies, Elgama also delivers complete Advanced Metering Infrastructure (AMI) solutions that help utilities manage large numbers of installed meters and handle data collection, storage, and analysis. These solutions bring together MDMS, communication infrastructure, and smart metering devices, and are based on open standards to ensure scalability and flexibility.

The smart meters and AMI equipment are manufactured in-house using state-of-the-art electronic assembly facilities at Elgama’s headquarters. Moreover, leveraging its investment in advanced automation, the Company provides electronic manufacturing services (EMS) for Lithuania’s thriving technology-focused community. Its current client base includes well known companies that are active in fields such as industrial networking, automation, and precision high-speed lasers. To meet the high demands of these two activities, Elgama relies on technological facilities based on modern, highly efficient and precise surface mount equipment.

“We are equipped to meet exacting technical requirements and deliver competitively priced products and services that represent great value for customers and end users. We invest in the best possible manufacturing technology to extend our capabilities and strengthen our reputation for quality.” – commented CEO Martynas Čereška.

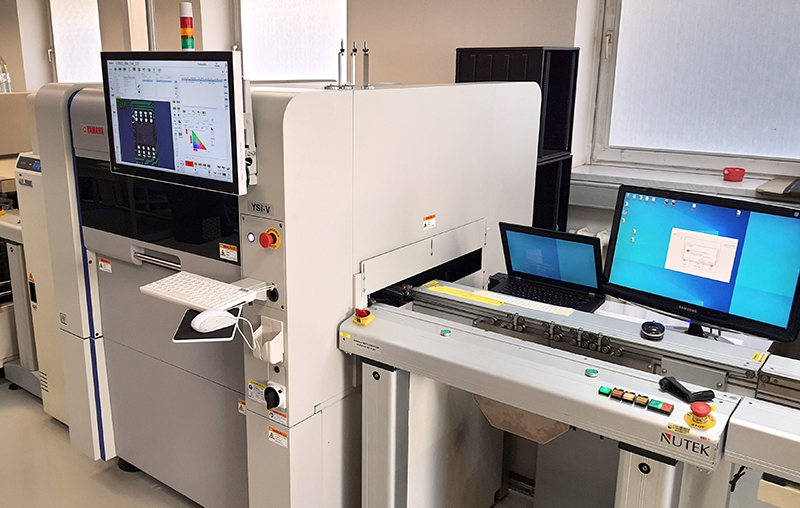

Accordingly, Elgama has recently installed a complete new surface-mount assembly line. Anchored by Yamaha’s compact YCP10 high-speed printer, the line also contains two Yamaha YSM20R premium compact component mounters, and the YSi-V high-resolution 3D automatic optical inspection (AOI) system. Together, they make up Yamaha’s unique 1-Stop Smart Solution.

The YCP10 compact printer delivers high throughput and ease of use within a small footprint, enabling efficient use of the factory floorspace. Selecting the YSM20R, the premium mounter in the YSM series, delivers class-leading 95,000 cph and ensures and broad component-handling capability without changing the head. Elgama’s two YSM20R mounters, positioned inline (figure 1), raise the overall throughput and enhance flexibility when setting up feeders to minimise changeover times.

An optional sATS30 auto-tray sequencer is also used, enabling non-stop operation and greatly simplifying the loading of the machine with tray-feed components such as ICs.

The AOI YSi-V 3D inspection device (Graphic 2) is equipped with multi-wavelength illumination, a laser for component-height measurement, and an optional four-angle camera that enables detailed assessment of individual solder joints. The data from the YSi-V can be fed back to enable process issues to be fixed quickly using software tools such as QA Option and the Mobile Judgement smartphone app that lets operators implement decisions from wherever they are in the factory.

YAMAHA industrial devices and robots are also available in Poland. They can be seen and tested in operation in the RENEX TECHNOLOGY AND TRAINING CENTER. Within this center RENEX Group, which is one of the largest Polish companies in the electronics industry and also a distributor of YAMAHA SMT and Robotics for Poland and the Balkan countries, pursues its mission of providing comprehensive services to the electronics industry. RENEX Group provides not only the equipment itself but also a wide range of consulting, service and training services. RENEX TECHNOLOGY AND TRAINING CENTER specialists help identify production problems and select appropriate technological solutions.

The Center also provides training in the field of implemented solutions. The center also houses an AUTHORIZED YAMAHA TRAINING CENTER, providing expertise in the operation and programming of industrial devices and robots, including SCARA robots, which allows users to take full advantage of their capabilities.