Standard inspection tools are no longer precise enough for working with microscale components. In this light, digital microscopy emerges as a leading tool in the study of micro and nanostructures. However, the most advanced tool is only as effective as the software that drives it. Software for digital microscopes enables image display on a monitor, collaboration among multiple specialists on a single image, and remote analysis by experts.

What is measurement software in digital microscopy?

Measurement software for digital microscopes is a specially designed IT system that works with the device. It allows for precise measurements of structures or other micro-objects based on the microscope image. Supported by advanced algorithms, the software can accurately determine parameters such as distances, angles, areas, or volumes, converting the microscopic image into numerical values.

However, this is not just an addition to the microscope but a crucial component influencing the quality, speed, and accuracy of research. The software not only increases efficiency but also brings benefits such as automated measurement, time savings, and integration with other digital systems.

Benefits and importance of using modern software in digital microscopy

Using modern software in microscopy brings numerous benefits, revolutionizing the field of research and analysis. One of the main advantages is the automation of the measurement process, which reduces the risk of human error and ensures more consistent results. This software allows for detailed analysis and comparison of details and the maintenance of comprehensive documentation of progress, which is crucial for quality control and process improvement. In the electronics industry, such advanced solutions enable meeting the challenges of modern technology and ensuring the highest product quality.

Another important aspect is time savings. Reducing the time spent on analysis allows researchers to focus on interpreting results without being disrupted by the measurement process. The mentioned software can measure with micron-level precision, surpassing traditional methods.

Choosing a digital microscope with intuitive software is an investment in objectivity and a standardized analysis process. These microscopes are equipped with built-in computers that allow for regular software updates. The ability to add new functions and applications enables users to adapt the device to current needs without the need for replacement, which is an additional argument in favor of such technology.

How to choose the right software?

Choosing the right software for digital microscopy is crucial to achieving the desired results. One of the most important aspects to consider is the compatibility of the software with the microscope. To avoid technical issues and ensure smooth operation, it is essential to check the technical specifications of the program and keep in mind the possibility of future updates. Another important element is measurement accuracy. Depending on the needs, different programs offer varying levels of precision.

The intuitiveness of the interface is also significant. The software should be easy to use, with an intuitive user interface that speeds up the learning process. Finally, it is worth paying attention to technical support. When choosing software, it is advisable to consider the reputation of the manufacturer, who offers technical support, regular updates, and cares about the product’s development.

One of the main reasons people choose software for digital microscopy is the desire to eliminate manual measurements, such as those performed with calipers. Using software, measurements are made directly on the microscope image, bringing many benefits. This increases the efficiency and accuracy of measurements, facilitates documentation and tracking.

Examples of software solutions

When considering suitable software for measurements in digital microscopy, it is worth noting the available market options. There are many diverse programs designed for digital microscopy. Among the applications that work with digital microscopes, it is worth noting TAGARNO’s offerings. One example is IMAGE COMPARISON, which allows for comparing two images and identifying deviations between the sample and the standard (golden sample). The usefulness of this application lies in guiding the operator visually, enabling them to quickly and effectively detect any irregularities.

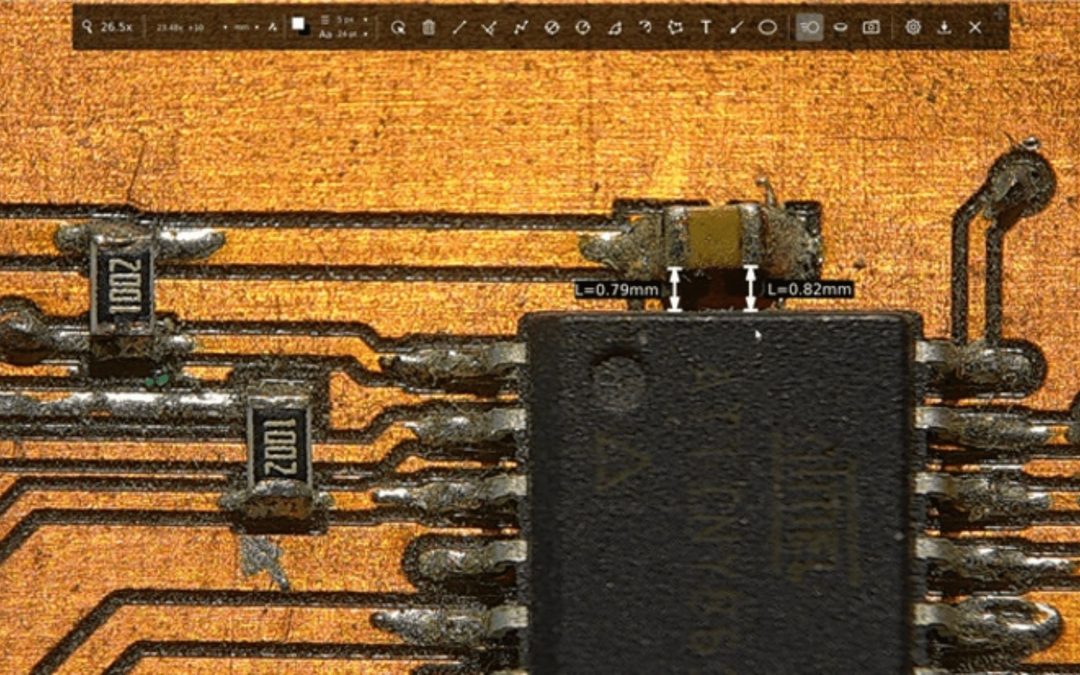

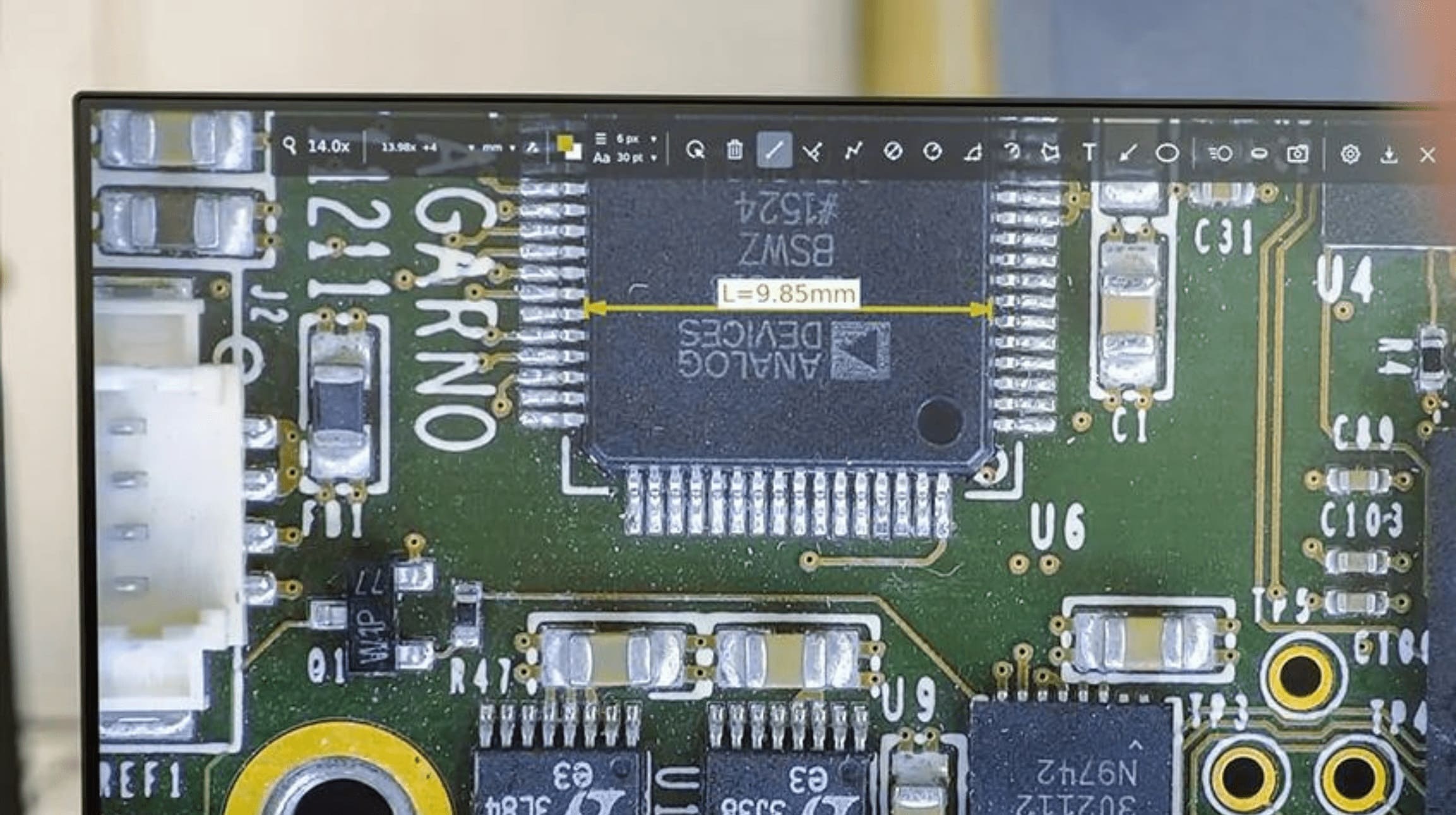

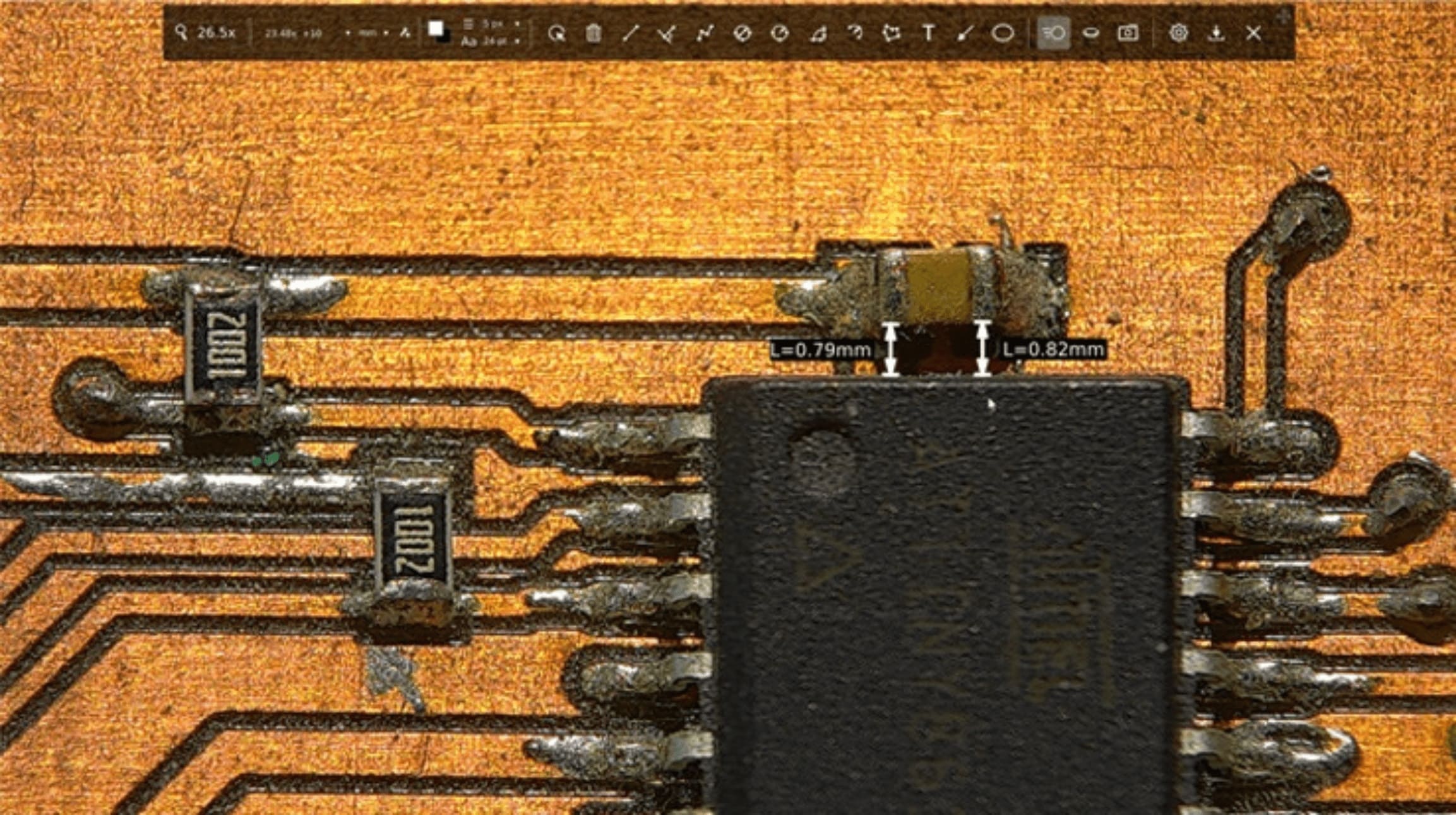

Another interesting tool is TAGARNO MEASUREMENT, allowing precise on-screen measurements with an accuracy of up to 0.003%. The application enables not only accurate measurements but also adding descriptions, annotations, or even forwarding information further along the supply chain. Another application, TAGARNO DXF OVERLAY, is designed with the PCB manufacturing sector in mind. It facilitates identifying even the smallest components during rework, presenting the operator with precise component contours in the form of a DXF file overlaid on the live image. The application’s functions allow quick searches for specific elements, adjusting the image size, and modifying colors or layers in the DXF file.

These applications are just examples of the possibilities offered by software for digital microscopes. It is worth considering choosing the right microscope with built-in software to enjoy greater work efficiency and accuracy in analysis. With them, digital microscopes like TAGARNO MAGNUS TREND FHD offer realistic images of the highest quality. Operators can use image comparison functions, making it easy to assess the quality of a component concerning the standard.

In summary

In the era of advancing miniaturization of elements used in the production and servicing of electronics, digital microscopes have become an essential tool in this industry. Choosing the right device is key to success; therefore, it is recommended to consult with an experienced advisory partner and test the microscope in real working conditions before purchase.

RENEX Group, one of the largest and most experienced suppliers in the electronics industry, proudly presents TAGARNO MAGNUS digital microscopes in its offer, including ZIP and ZAP models. With its long-standing presence in the market, RENEX guarantees professional support at every stage of cooperation – from technical advice to the opportunity to test the offered devices.

At the RENEX Technology and Training Center, you can personally experience the advantages of TAGARNO microscopes by testing them in real production conditions. The group also offers the possibility of conducting tests directly at the customer’s site, which is a unique convenience in the process of choosing the best solution. In its offer, RENEX Group provides not only technologically advanced devices but also a wide range of services, including consulting, training, and research and development services, aimed at supporting the development of enterprises of our clients and partners.

For more information, you can contact RENEX’s technical and sales advisors at dth@renex.pl or visit the website.