In today’s dynamically changing business world, managing energy and resources in the production process is transitioning from a trend to a necessity. Both corporations and smaller enterprises realize that success lies in achieving an optimal balance between equipment quality and operating costs. This means that developing solutions that allow for faster, more precise, and more economical operations is becoming imperative.

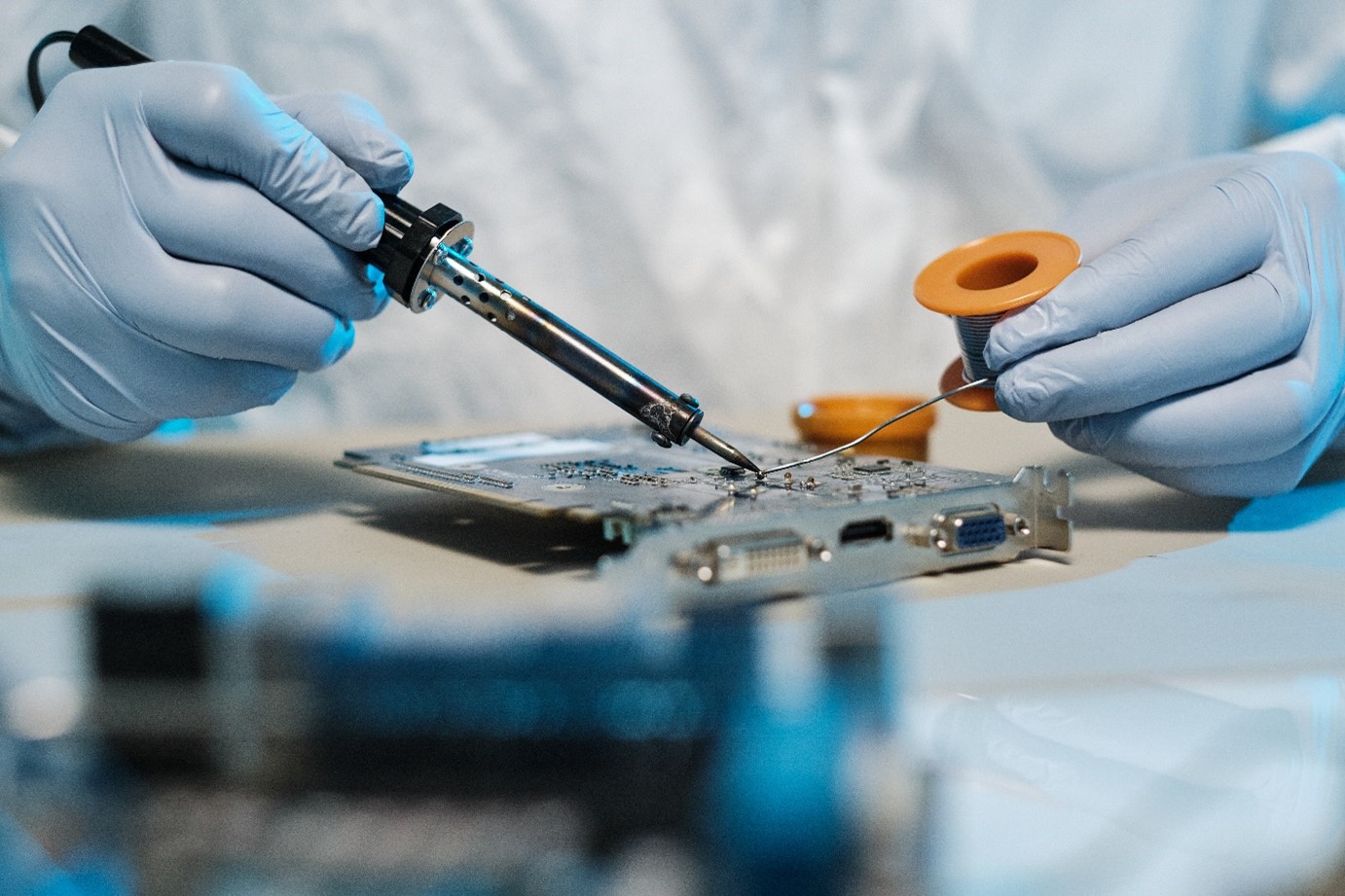

An integral part of many production processes is soldering, which requires the highest standards of precision and quality. Soldering, being a stage where various elements of the electronics are connected, inherently demands attention to detail, as any imperfection can lead to significant problems, such as shorter product lifespan or even malfunction.

High-quality soldering ensures better material connections, translating to longer life and efficiency of the entire system. It is precise soldering that allows for creating durable and reliable connections capable of withstanding high temperatures and other extreme conditions without the risk of damage or failure. Precision in this process is crucial to ensure even heat distribution and perfect fitting of components, which in turn guarantees greater stability and better performance of the final product.

It is essential to use tools that are not only reliable but also durable and efficient. The use of appropriate equipment can also minimize the risk of human errors, which are often the primary cause of problems in the soldering process. Well-designed tools enable maintaining proper working conditions, allowing for precise and effective soldering, even in the most complex projects. Proper technique, combined with professional soldering equipment, is thus the foundation for achieving success in any production-related endeavor. Therefore, choosing tools that are not only reliable but also durable and efficient becomes a priority.

Both large corporations and smaller enterprises pay attention to details that can significantly improve the production process. Managing temperature during soldering is one of those aspects that deserve special attention, influencing the quality of execution and the durability of soldering tips, which directly reduces costs associated with their replacement.

Proper temperature management ensures optimal component connections, protecting them from thermal damage that can occur at too high temperatures. This not only protects sensitive components but also ensures even tin distribution, which is crucial for the durability and functionality of the final product. Additionally, temperature control is important from an ergonomic standpoint of the soldering process. It ensures process stability, enabling repeatability and predictability of results, which is essential in industrial production where high quality and consistency are required in every manufactured unit.

Proper temperature management also means that soldering tips have a longer lifespan, reducing costs associated with their frequent replacement. Long-term use of high-quality tips is not only economically beneficial but also promotes sustainable development by reducing waste and encouraging more responsible use of resources.

When choosing an optimal soldering station, it is necessary to analyze many factors such as functionality and ergonomics of the device. Investing in equipment that combines modernity with functionality, such as the PACE ADS 200, can revolutionize the approach to the soldering process, making it not only more efficient but also user-friendly and environmentally friendly. Emphasizing these aspects, it is worth noting innovative soldering stations like the PACE ADS 200, equipped with modern automatic temperature adjustment functions.

Using this technology allows extending the lifespan of soldering tips, directly translating to savings related to their replacement. The advanced energy management system makes the station environmentally friendly while enabling the execution of the most demanding projects, maintaining the highest quality standards. Importantly, this device is designed with various user groups in mind: from professionals to servicemen to hobbyists.

The use of modern soldering stations such as the PACE ADS 200 can significantly increase efficiency and reduce operational costs in both large enterprises and smaller workshops. Choosing top-tier equipment means investing not only in better quality soldering but also in work comfort and safety. In the long term, such an investment can bring real benefits, allowing for avoiding downtime and saving energy, which, in light of rising energy costs and increased emphasis on the environmental friendliness of production processes, becomes not only a necessity but also an important element of the strategy of every entrepreneur striving for success in a competitive market.

PACE products are available in the RENEX Group’s offer, a leading distributor of top-class equipment for industry and individual users, being the official distributor of PACE products since 1994. Continuing a long-term partnership with the brand, RENEX Group offers professional advice and access to the latest technologies in the field of soldering.

To explore the full range of PACE soldering stations, it is worth visiting RENEX Group’s online store at sklep.renex.pl. Currently, potential customers can take advantage of attractive promotional prices, enabling the purchase of equipment at reduced prices. For those seeking professional advice, RENEX Group invites you to contact a Technical Sales Advisor. The specialist will help tailor the right equipment to individual needs and requirements.

Additionally, at the RENEX Technology Center, it is possible to personally familiarize oneself with the functionality of the offered devices by testing them in practical conditions. Choosing RENEX Group ensures professional support at every stage of the purchasing process.