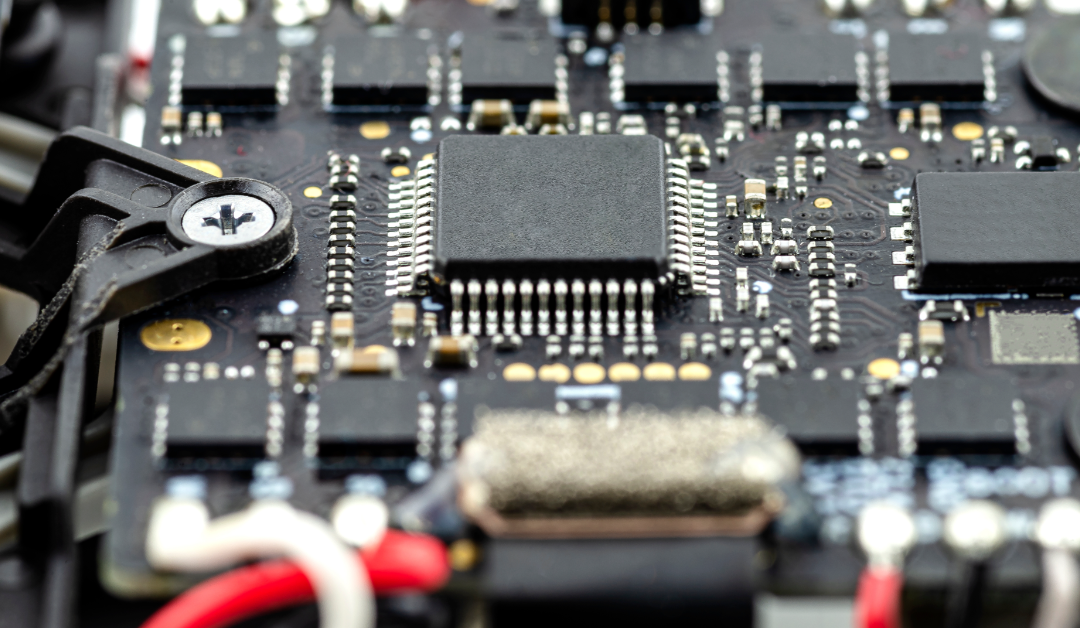

The English term “rework” in electronics production refers to situations where an electronics unit requires the replacement of one or more already soldered components. This often occurs when a defect is detected at one of the quality control stages during production. In some circumstances, this term is also used in reference to warranty and post-warranty repairs.

Rework in electronics is the process of repairing or modifying electronic systems to improve the functioning of devices or adapt them to new requirements. This process can involve various tasks, such as replacing damaged components, improving soldering, or modifying the design of the system.

Why is Rework Important?

Rework plays a crucial role in the electronics industry because it helps maintain high quality in produced devices and optimize their performance. Utilizing rework helps avoid resource wastage and reduce production costs.

Moreover, rework allows for the repair of devices that have been damaged during use, extending their lifespan. This enables users to use devices for a longer time, which translates to less electronic waste and a lower environmental impact. Rework is also important from the perspective of warranty and post-sales service.

The ability to repair devices allows manufacturers to offer long-term support to their customers, which in turn affects customer satisfaction and loyalty, as well as a positive reputation for the company in the market.

What methods are used for rework?

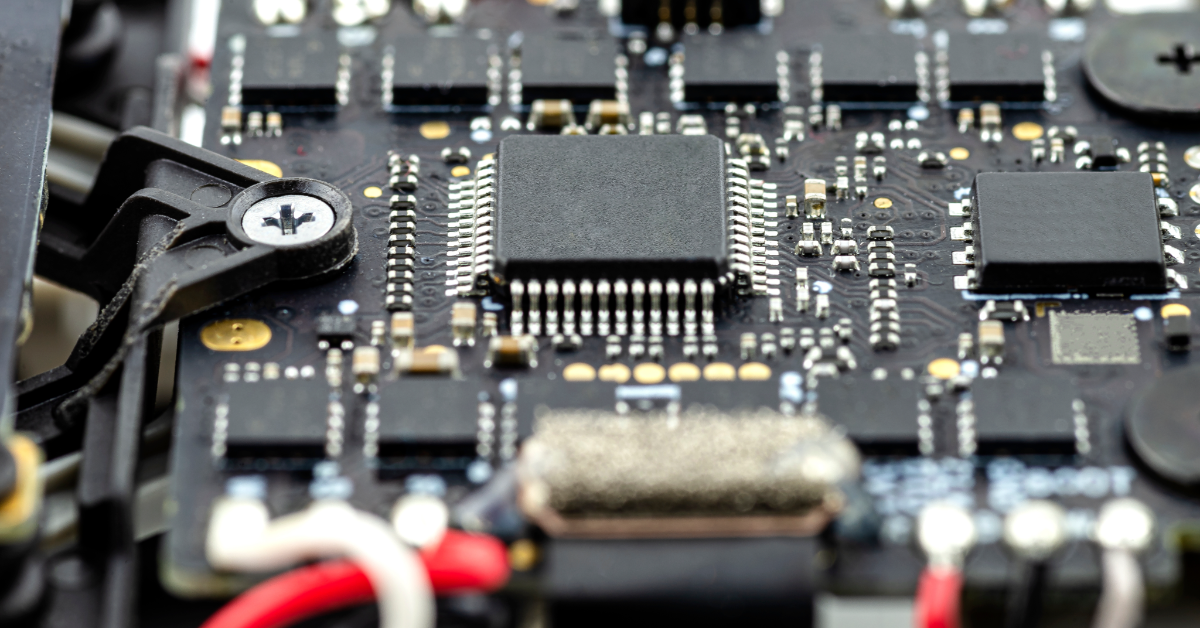

Rework in electronics can be performed using various methods, depending on the specific case and requirements. Some popular rework techniques include manual soldering, hot air soldering, wave soldering, or using a soldering station with an infrared heater. The choice of the appropriate method depends on the type of components to be repaired or changed, as well as the precision and quality requirements of the work.

Manual soldering is one of the most basic rework methods and is often used for simple repairs, such as replacing a damaged component or improving a connection. This method involves using a handheld soldering iron and solder to create or improve electrical connections. Although manual soldering is simple and economical, it requires some skill and experience and is not suitable for repairing very small components or high-density circuits.

Hot air soldering is a rework method that uses a stream of hot air to melt the solder on the component contacts. This technique allows for precise and quick removal and mounting of SMD (Surface-Mount Devices) and BGA (Ball Grid Array) components. It requires a specialized soldering station with temperature and air flow regulation and appropriate nozzles.

Wave soldering is a technique that allows for mass soldering of components, primarily in serial production. For rework, it can be used to repair larger batches of devices. Soldering stations with an infrared heater, on the other hand, enable precise and even heating of the working surface, which is particularly useful when repairing and replacing integrated circuits and components with large contact areas.

In practice, the choice of rework method depends on many factors, such as the type of damage, the type of components, and the precision and quality requirements of the work. Regardless of the chosen method, it is essential to have the appropriate skills and tools to effectively perform rework and thus improve the quality and functioning of electronic devices.

Training and Certifications

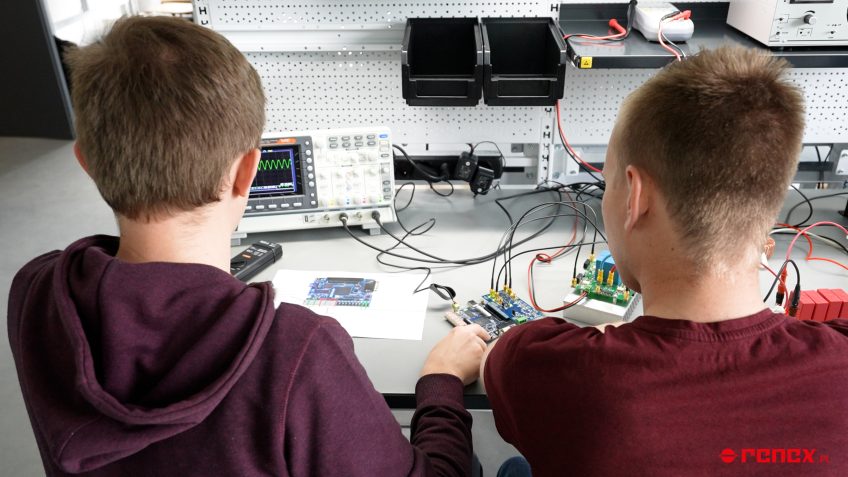

Education and training are key elements in the electronic rework process. Through specialized courses, technicians gain the necessary knowledge and skills to effectively repair and service devices. Many organizations offer rework training, both at the basic and advanced levels. The most recognizable standards in the field of rework are IPC-7711/21 and IPC-A-610.

Rework training often includes practical exercises using real devices and tools. This allows participants to gain experience while ensuring they can handle various repair situations in real working conditions.

Many training programs also offer certification upon course completion, which can be an added advantage for individuals seeking work in this field. As electronic technologies evolve, rework specialists must continually expand their knowledge and skills. Therefore, participating in training, workshops, and industry conferences is essential to learn about the latest trends, techniques, and tools used in the repair and servicing of electronic devices. This way, rework professionals gain a competitive edge in the job market while providing their clients with top-quality services.

Equipping rework workstations

When deciding to undertake rework on a specific batch of products, an enterprise must not only engage skilled workers but also appropriately equip such workstations. Efficient work with BGA components, allowing for their safe assembly and disassembly, requires more advanced equipment than the standard soldering station found in every electronic service center. Below we discuss two example solutions to this problem.

Zestaw REECO RA300 Kit for SMD/BGA assembly and disassembly

The kit consists of a quartz preheater, a hot air station, and an XYZ stand. The role of the first element – the preheater – is to raise the temperature of the entire PCB to a temperature close to (but not reaching) the one necessary for solder reflow. For example, assuming lead-free solder reflow occurs at temperatures above 200°C, the user can use the preheater to raise the temperature of the electronics from room temperature to about 140°C. This facilitates further work and disassembly, reduces stresses that could arise from spot heating of the laminate, and consequently reduces the risk of damaging often valuable components.

The preheater used in this kit employs quartz heaters that efficiently reach and transfer temperature. The device has high power, which, combined with a large heating surface – A3 format – allows heating both large and demanding PCBs, including multilayer and large ground plane boards. Importantly, the work area is divided into three independent heating zones, allowing optimization not only in terms of soldering quality but also in terms of energy consumption. Many boards are smaller than A3 format. When working with them, it is much more efficient to activate only the necessary number of fields.

The preheater’s software allows defining two operating modes: constant heater temperature or active thermocouple. In the first case, the device will maintain the heater temperature during operation at the set level with an accuracy of 5°C. In the second mode, the user attaches thermocouple tips to a selected critical point on the PCB. The device uses these sensors to read the temperature at that point and adjust the heater power to maintain it within the specified range.

The second component of the REECO RA300 kit is the hot air station, also known as hot air. Using the assigned software, it connects to an external computer or laptop. This system allows setting a soldering profile for a given task and saving it. This way, it is possible to create a personal database of profiles from previous work and later return to them when rework is needed on the same board or system.

The third component of the kit is the stands used to hold the PCB being worked on. They operate in an XYZ system, where the Z stand serves as the base for the hot air station head. The system’s wide range of motion enables work on the entire heating surface – A3 format.

REECO RS300 Device for SMD/BGA Assembly and Disassembly</h4>

An alternative solution to the kit discussed above, also allowing efficient rework, is the REECO RS300 Device for SMD/BGA Assembly and Disassembly. It is the latest and most advanced device in this series. It combines all the functions of the previous model in a compact unit.

Like the previously discussed kit, the REECO RS300 Device also features a high-power A3 format heating plate divided into three independent zones, software allowing profile saving, a hot air station, and XYZ system stands.

However, the significant difference from the previous kit is that the device has a compact design with a built-in control computer. This allows operating the device using a touch screen and user panel without the need to connect an external laptop – which can be crucial in companies operating under high electrostatic safety regimes.

Collaboration with RENEX Group

The manufacturer of REECO devices is RENEX Group, providing comprehensive support for the electronics industry. Besides equipment, the group offers a wide range of advisory, training, and research and development services aimed at supporting the growth of its clients and partners.

Within the REECO line, the group has also developed and supplies a series of specialized robots, modular furniture for EPA zones, and antistatic clothing. REECO products and a wide range of other devices and robots from the REECO offer can be seen and tested (also on your own components) at the RENEX TECHNOLOGY AND TRAINING CENTER in Włocławek.

Interested parties are invited to contact dth@renex.pl.