Soldering cables and wires in the course of creating electronic packages is a subject that is often downplayed – “after all, what could be difficult about soldering a cable”. Such an attitude can be encountered even in large EMS companies, where the greatest importance is often attached to automated SMT or THT assembly. As a result, in the products coming out of such lines, you can find solders that look more like lumps of tin than proper connections.

The first step here, of course, is to identify the problem in this regard. Unfortunately, this often happens only when the manufactured electronic packages begin to return in the course of complaints or information from an unsatisfied contractor. Practice shows that a small but neglected element, which is often the soldering of cables, can affect the quality of the entire device. Properly performed surface and through-hole assembly of components – seemingly the more difficult stage of the process – can easily be overshadowed by errors and defects resulting from a single badly soldered cable.

The most common mistakes arise from poor alignment of the wire with respect to the solder field or terminal, a poorly selected amount of solder, too much or too little stripped insulation, or improperly performed tinning. As a consequence, they can result in mechanically defective connections, electrical short circuits or, as in the case of the aforementioned lumps of solder, a simple inability to visually verify whether the contact is correct. All of these constitute defects – either visible at first glance or hidden, which will reveal themselves after time. They result in measurable financial losses – directly related to complaints or rework, or those less obvious – resulting from loss of reputation or subsequent orders.

Cable soldering – Training courses

The natural solution to competence gaps is, of course, adequate training. By adequate, it should be understood here as realized in the field of IPC standards – the most widely used standards in the world for the design, manufacture and repair or evaluation of electronics packages, as well as the assembly of wire harnesses – and thus setting quality classes recognized by principals and contractors regardless of the market in which they trade.

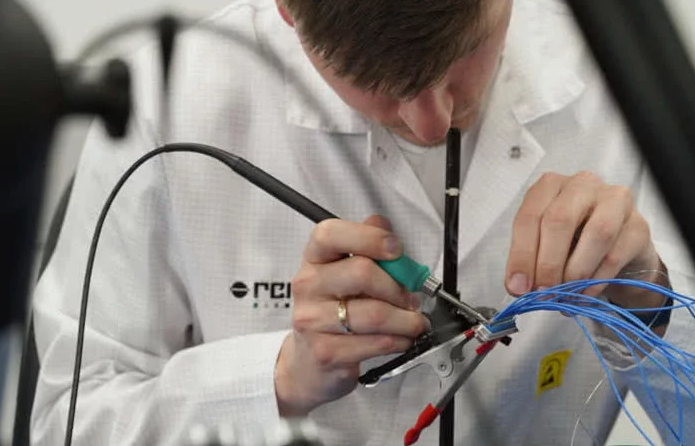

One of the best equipped and at the same time the largest center in Central and Eastern Europe providing specialized training in cable soldering and IPC standards is the RENEX Electronics Education Center in Poland. It has been part of RENEX Group for more than 20 years and operates within the RENEX Technology and Training Center in Wloclawek. The purpose of the unit is to increase the competence of specialists in the design, production and repair or evaluation of electronics packages, as well as the assembly of wire harnesses, and to promote proper – high quality standards. The center offers training courses for electronics engineers covering the full range of IPC standards, as well as courses on antistatic protection issues, and its trainers, as top-ranking specialists, co-create further revisions of standards published around the world. The Polish entity prides itself on its vast experience in training specialists at home and abroad and, what is particularly important, its authorization to conduct courses and award certificates at the IPC trainer level.

In addition to courses in IPC standards, the center also provides a wide range of proprietary training in the topics of proper assembly of electronic packages, operation of PACE equipment, proper use of EPA zones, ESD protection or ESA (European Space Agency) norms and standards.

In terms of the problem at hand, the training course “Requirements and Acceptances for Cable and Wire Harness Assembly” is key to acquiring the relevant competencies. It is aimed at those who are directly involved in the assembly or inspection of connections made with wires and cables, and is designed to provide interested persons with the broadest possible practical and theoretical knowledge of the IPC/WHMA-A-620 standard. In the course of training, trainees acquire knowledge in such areas as wire preparation, soldering in configuration with various types of terminals, connecting insulated wires (IDC), crimping, creating splices, ultrasonic welding, assembling a connector, measuring wires, connecting coaxial and biaxial cables (coaxial and twinaxial), protecting and electrically shielding wire bundles, routing, or carrying out electrical and mechanical tests of manufactured connections. Training is available at two levels – apart from training for specialists, the center also conducts courses that confer the highest level of certification – that of trainer. Higher-level training courses are aimed not only at those directly involved in the inspection of soldered cables or connections made with wires, but also those responsible for training employees who carry out this range of duties. It is also worth mentioning that during the practical classes on wire harness making, participants have the opportunity to work with tools and equipment used , for example, in the military and SPACE industries.

Automation of the cable soldering process

The next step and also the solution to the problem of errors in the installation of cable connections is to automate this process. Also in this area, extensive consulting and research and development activities are provided by the RENEX Group.

The company’s specialists help identify production problems and select appropriate technological solutions. Their example is the REECO series of robots, particularly the Soldering Robot that is part of it. The device can operate both in-line and off-line and allows soldering joints to be created with high precision and repeatability. At the same time, it is cost-effective in the production of electronics already in medium runs. The center also provides training in robotic solutions, providing expertise in operating and programming industrial equipment and robots, allowing users to take full advantage of their capabilities. It also assists in adapting processes in companies already operating in the market. This is particularly true for those entities that are developing or implementing their own production of electronic packages and devices, or those seeking to automate their processes, broadly defined here, through the implementation of industrial robots. The center also provides consulting services in the field of ESD protection and the creation and proper maintenance of EPAs (electrostatic discharge protection zones).

Podsumowanie

Downplaying the element of electronic package production that also includes soldering cables and assembling wires and harnesses can have far-reaching financial and image consequences. The solution is to gain knowledge through training and qualification growth. Qualifications in this sphere can be obtained at the IPC Authorized Training Center – RENEX EEC. Support in this area is provided by the RENEX Technology and Training Center.