REECO’s ESD Softshell Sweatshirt (designation: CE-SOFTSHELL.SFTL) was developed for use both directly in EPA-type areas where electromagnetic-sensitive electronics are produced, as well as in related areas such as warehouses, aisles, production halls and outdoor spaces.

“We are expanding our range of warm ESD sweatshirts as a result of the numerous requests we have recently received from our partners and customers. It promises that the upcoming winter season will require everyone to reduce energy consumption and heating in spaces where such cutbacks are possible. This includes, for example, warehouses and loading aisles. Often these areas are either subject to an anti-static protection regime or handled by people who, when moving through different zones, must maintain this regime in their attire. Hence the apparent market need for sweatshirts that protect against the weather while maintaining ESD protection standards.” – commented Ms. Marzena Szczotkowska-Topić and Mr. Predrag Topić, owners of RENEX Group.

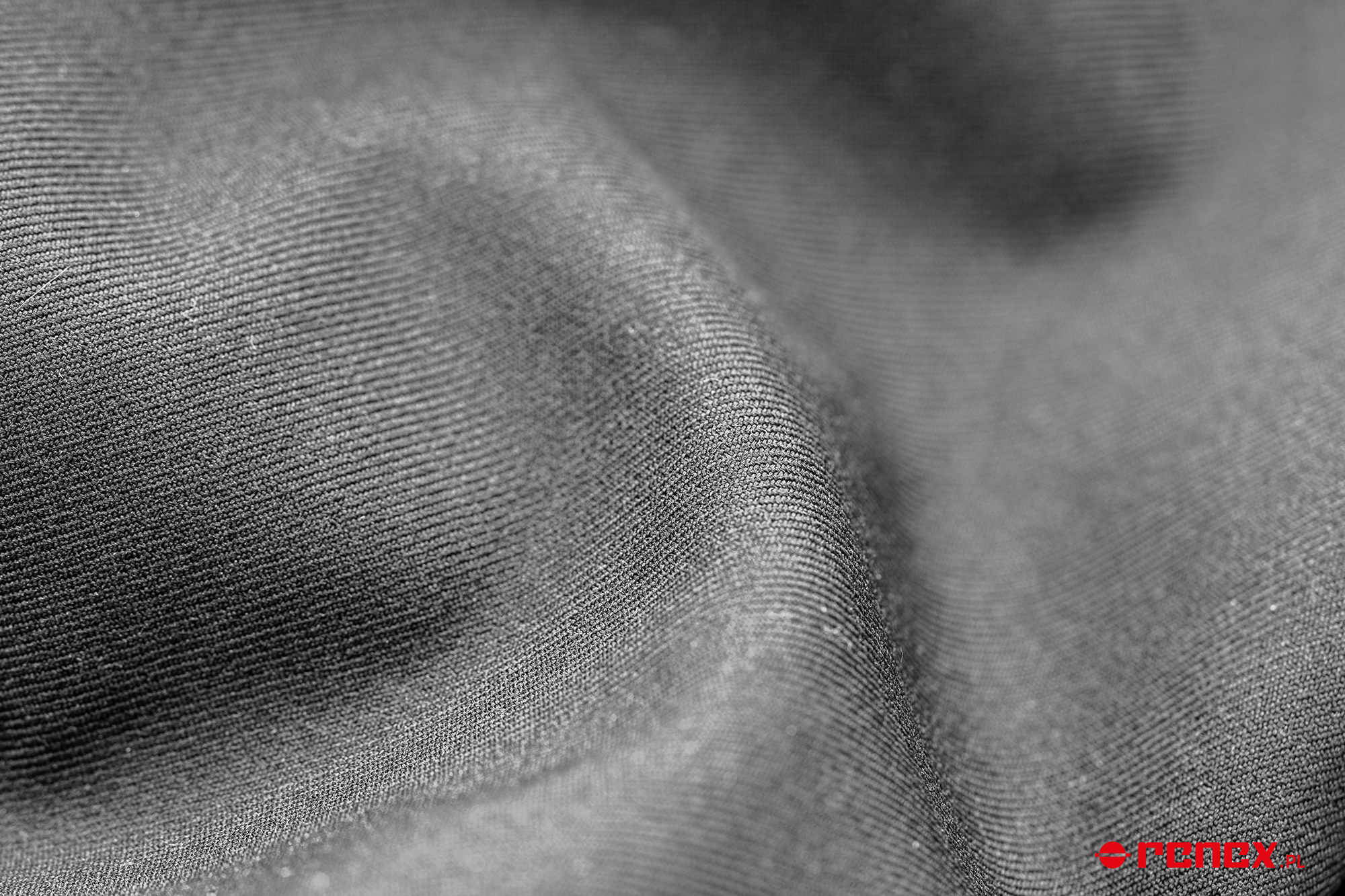

REECO’s new ESD Softshell Sweatshirt has been made of materials that in their structure contain electrically conductive elements in the form of carbon fibers. The zipper, as required, has been additionally covered, and the sweatshirt meets the requirements specified in PN-EN 61340-5-1. In keeping with the standards of the entire REECO product line, the Softshell Sweatshirt is available in a full range of sizes – from 2XS to 2XL. The model is available in black, in a universal cut: with a raised collar and two lower pockets. The RENEX Group has introduced the new product as an expansion of their existing wide range of REECO clothing. It includes specialized garments designed for use in, among others, EPA zones and cleanroom type areas.

The materials used meet the stringent requirements of this type of space. Clothing designed for EPA zones – that is, anti-static or ESD clothing – does not generate electrostatic discharges – which are dangerous to sensitive electronic components. Clothing designed for cleanroom zones is made of materials that do not emit dust and particles into the air. This is essential when working with advanced technologies in, for instance, the pharmaceutical, medical or space industries. REECO clothing lines, despite their specialized purpose and the materials used, are manufactured to provide the greatest possible comfort and a wide range of cuts and colors. At the same time, their high quality allows them to be used for a long time.

Other than clothing, RENEX Group has developed and supplies a series of robots, specialized equipment and versatile, anti-static industrial furniture under the REECO brand. REECO robots are turnkey solutions. Each one is a fully automated, self-contained unit that can be implemented in an operating or newly established production line. They do not require advanced design, planning and integration processes, and no expertise or experience is needed to control their operation.

The Polish REECO product line has been expanding into foreign markets in recent years. In recent years, RENEX Group has seen rapid growth in exports of REECO product groups. In the recent period alone, distribution has been expanded to Japan, the Netherlands, Belgium, Ireland, Switzerland, the United States, Ecuador and Saudi Arabia, and many more.