As announced by its distributor, RENEX Group, YAMAHA SMT has launched the new YRi-V 3D hybrid automatic optical inspection (AOI) system.

The YRi-V 3D was developed as a higher-end version of the YSi-V 3D AOI model, which has been available until now and is very popular in the industry.

The new device features a newly developed inspection head equipped with a high-speed, high-resolution camera, an upgraded 3D projector, and a high-performance GPU, among other features. According to a study conducted by YAMAHA Motor in May 2021, the YRi-V achieves the fastest inspection speed in the industry. In addition, the new model allows inspection of ultra-small components and detection of scratches, cracks, chipped areas and the like with mirror-surface finishes, a difficulty until now.

Market context and product outline

The efficiency of SMT processes directly affects the market value of products. Therefore, precise and automatic quality control of the assembly of all components is becoming a necessary element of modern lines. The SMT field in recent years has seen the shift toward miniaturization, increased component density and differentiation. Also more recently, the use of thin and extremely small WLCSPs and FOWLPs, which have specular gloss on the package surface, has risen significantly in the market.

The YRi-V accommodates these changes and demands of the market early on. This AOI system dramatically improves inspection ability in terms of both speed and accuracy, with greater detection capability for 0201 size (0.25 mm x 0.125 mm) ultra-small components and mirror-glossed components.

Product features

1) High speed and high precision

The newly developed inspection head features the current 12 μm and 7 μm resolution lenses as well as a new 5 μm resolution lens compatible with 0201 size ultra-small chip components. The YRi-V gains all-new lighting with increased luminance and is also equipped with the industry’s fastest high-speed, high-resolution camera with an increased frame rate. Employing a high-performance GPU yields faster image processing capabilities that achieve incredible speeds, almost twice that of the current YSi-V TypeHS2 at 7 μm and 1.6 times at 12 μm.

Updating the 3D projector has also enabled even more precise inspections, with both measurement accuracy and range doubled compared to current models and high-precision measurement now possible for up to 25 mm in height.

Furthermore, by combining the 5 μm lens and an 8-direction 3D projector, it is possible to perform high-precision 3D inspections of 0201 size ultra-small chip components and fine pitch components with imaging at high resolutions without the effects of component blind spots.

2) Greater functionality

The inspection head’s new coaxial lighting bolsters the capability to detect scratches, cracks and chipped areas on mirror-surface components and the detection sensitivity has also been improved.

In addition, the revised conveyors expand the range of compatible PCB lengths and it is possible to flexibly handle longer, 1,200 mm PCBs (with optional fittings). In a dual-lane setup, the freer adjustability of fixed positions for rails 2, 3 and 4 have improved versatility when linking up with other equipment.

3) Improved usability

Intuitive operation is possible with the new GUI’s next-generation design. Further, automating various functions, incorporating AI and more has enabled us to offer a full range of support functions for creating inspection data and for tuning data without the need for a high skillset among operators.

During data conversion:

It is possible to convert CAD/CAM/YGX data into inspection data in a single step. In addition, the machine is compatible with Gerber data as standard and automatically generates virtual board images.

When creating data:

It is easier to create inspection data with features like offline data creation, individual 3D projector condition settings and automatic creation of through-hole data from raw board images.

When tuning data:

Data tuning time is halved by eliminating inspection frames (automatic calculation), automating lighting parameters and automatic position correction that accurately accounts for the degree of component misalignment.

In addition, AI deep learning identifies the component type from the component image and automatically sets the ideal component library. It also greatly promotes further automation and labor saving, such as automating new component library creation and aiding with secondary visual checks and decisions.

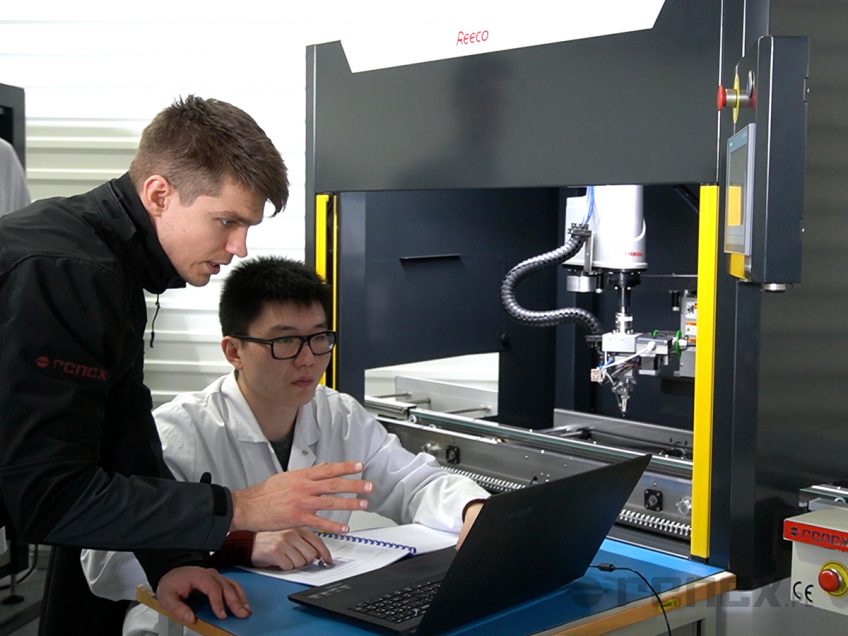

Exclusive Distributor of YAMAHA SMT and YAMAHA ROBOTICS – RENEX Group

RENEX Group is the exclusive distributor of YAMAHA SMT and YAMAHA ROBOTICS in Poland and countries of Central and Eastern Europe. YAMAHA equipment, including industrial robots, SMT production equipment, SCARA robots and other products from the RENEX offer can be seen and tested in operation in the test conditions of production lines (also with own components and subassemblies) in RENEX TECHNICAL CENTER and DEMOROOM. Apart from the equipment, RENEX Group provides a comprehensive range of consulting and advisory services in the field of automation of production processes.

The Center also conducts training in programming and operation of both SMT devices and industrial robots.

If you are interested, please contact RENEX Group Technical and Sales Consultants – dth@renex.pl.